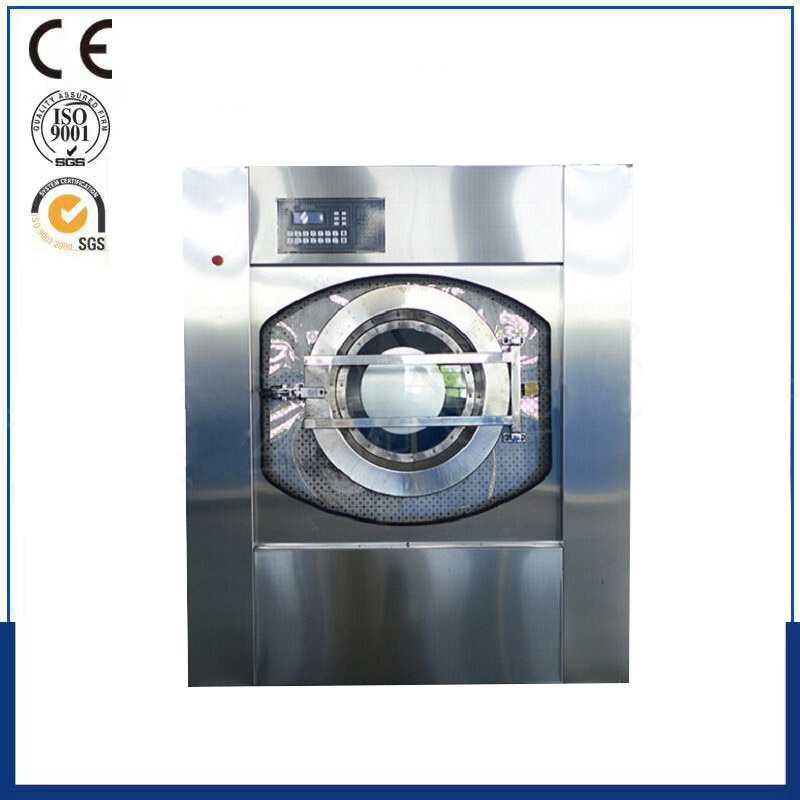

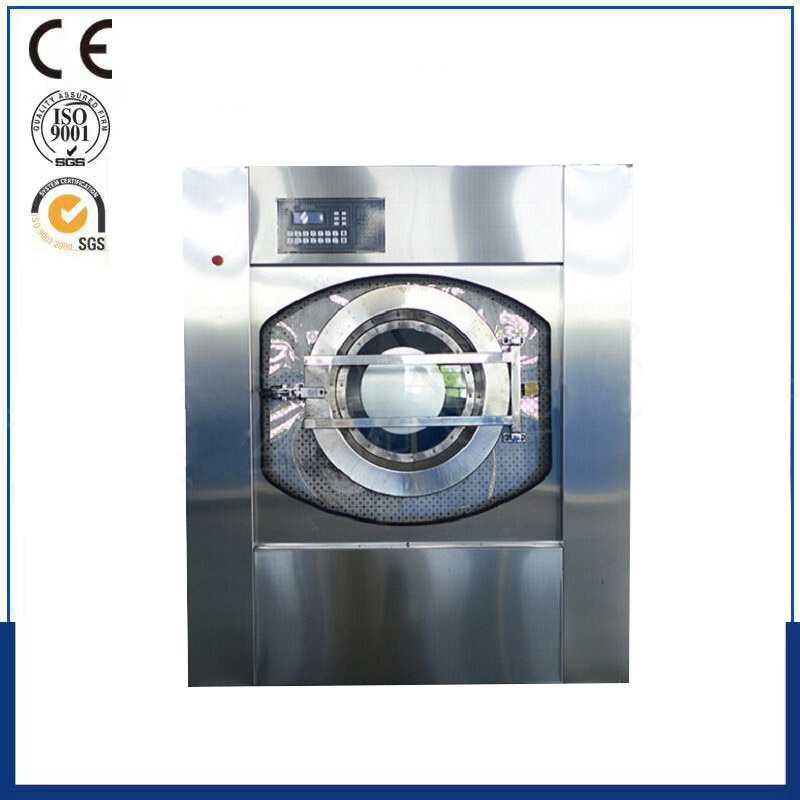

1. The fully automatic Industrial Washing Machine is centered around a program controller and equipped with electrical control components such as water level switch, drainage selection switch, rinse selection switch, wash selection switch, safety switch, etc., forming a program control circuit to control the on/off of load components such as inlet valve, motor, drainage electromagnet, buzzer, etc., achieving program control of inlet, washing, drainage, rinsing, dehydration, etc.

2. The microprocessor and its interface circuit constitute the program control system of a fully automatic industrial washing machine. The main microprocessors used on program controllers are 4-bit and 8-bit. The data processed by the microprocessor only consists of two digits, 0 and 1. In the interface signal, 1 and 0 correspond to high and low levels, respectively. The microprocessor interface circuit includes: DC power supply circuit, reset circuit, clock circuit, time base circuit, key input circuit, display circuit, buzzer circuit, load drive circuit, water level switch, and safety switch input circuit.

3. The controller of a fully automatic industrial washing machine mainly includes four circuits: load drive circuit, button input circuit and display circuit, safety switch and water level switch input circuit, and protection circuit. The specific functions are as follows.

4. Load circuit: also known as strong current control circuit, is a circuit that controls the on-off of AC 220V voltage. The power supply terminal of this circuit is connected to a 220V power supply, and the output terminal is connected to the load component.

5. Key input circuit and display circuit: This circuit is a fully automatic industrial Washing machine operation command input circuit. The buttons are arranged in a certain matrix. When different buttons are pressed, the signal is input to the microprocessor CPU through the interface of the row where the button is located. The CPU recognizes the function of the button and retrieves the data from the memory. The control signal is output through the output interface of the microprocessor.

6. Safety switch and water level switch input circuit: Its function is to transmit information about the on/off status of the switch to the microprocessor, so that the microprocessor can control the operation program.

7. Protection circuit: The computer-controlled fully automatic industrial washing machine is equipped with hardware automatic protection and software automatic protection during the washing process.

Phone

Phone

Comment

(0)